The sea water has to be carefully filtered before being run through the reverse osmosis membrane at very high pressure (around 800 psi). This typically happens in three stages, each with progressively finer filtration.

- The first stage is a simple sea strainer to keep out large debris, jelly fish, etc.

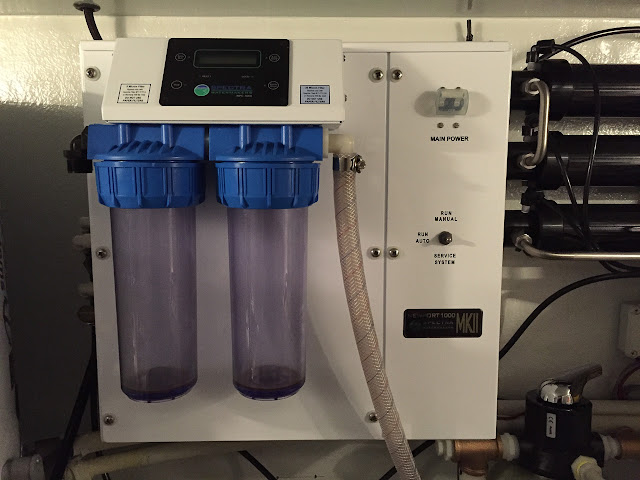

- The second stage is a standard 2.5" x 10" cartridge filter using a 20 micro fabric filter element.

- The third and final stage is a similar cartridge filter, but with a 5 micron element

|

| Standard 2.5" x 10" 20 and 5 micro filters |

Talking to people and doing some research suggested two additional things we could do. The first is a plankton filter which is like the standard cartridge filters, but uses a fine mesh stainless steel basket. What's plugging up the filters is microbial life in the sea water, and the plankton filters do a much better job of catching it. And the stainless basket can be rinsed clean and doesn't need replacement. That sounded like a big improvement, but it still sounded like I was going to be opening sea strainers and cleaning them all the time which is not something I was looking forward to.

The other alternative sounded even better, and involved adding a media filter. A media filter is a very simple filter that runs the water through some sort of "media" like sand or gravel. Whatever is in the water gets trapped in the sand, and clean water comes out the other side. This is exactly the principal that makes ground water safe to drink when surface water is not. The ground water starts out on the surface, but gets filtered as it soaks through the ground. Media filters are used for pool filtration, and a wide range of drinking water filtration. They work equally well for filtering sea water for a water maker.

One of the best parts about a media filter is the way you clean it. All you need to do is back flush it, which is simply running water through it in the reverse direction, and dumping the outflow overboard. The reverse flow dislodges all the trapped crud and flushed it away. There are no filters to open, baskets to clean, and no sea water getting splashed around inside the boat. It's just a matter of switching a valve and running the flush pump. Not THAT sounded appealing, so this is the direction I went.

At the Seattle Boat show I came across a vendor who had just the sort of filter I was looking on display, so I arranged to buy it from him at the end of the show at a discounted price, with "some assembly required".

|

| Media Filter |

With filter in hand, the next question was what to use for filter media. Everyone I talked to said to use "pool filter sand", whatever that is. I couldn't find anything that actually described how fine the sand should be, or what size material it would filter out. As best I could tell, I should expect to filter out particles anywhere from 20-100 micron in size. I honestly didn't know how much that would help the 20 micro filters already in place, but figured it could only help. I called around and found a pool supply shop that despite it being February, was open and could sell me "pool filter sand", whatever that is.

The media filter is an 8”x30” fiberglass filter cylinder with control valve. The valve has 3 plumbing ports; one for incoming sea water, one for waste discharge, and one for filtered water outlet. The valve also has three control positions:

- Forward Filter: This is the normal operation position. Water enters the inlet, flows through the filter media, then out the outlet to the rest of the water maker. As material is filtered out and collects in the media, there is an increasing pressure drop across the filter, and eventually it needs to be cleaned with a back flush.

- Back Flush: In this position, water enters the inlet, but flows through the media in the reverse direction such that is dislodges the trapped material. And the outflow is directed out the waste outlet and overboard. All you need to do is run the filter in back flush for 15-30 minutes, and it cleans itself. That's my kind of maintenance.

- Forward Flush: When you are back flushing, you do so with sea water. As sea water is flowing through and flushing our previously trapped material, that same seawater is being filtered by the media as it flows through in the reverse direction. Much less material is captured because it only runs for maybe 30 minutes, but there is still some. When you resume normal operation for forward water flow, you are now essentially back flushing what you trapped during the backwash. Make sense? This is what Forward Flush is for. It runs water through in the normal forward direction, but direct the outflow out the waste port and overboard. So after a back flush, you do about 1 minute forward flush to clear out anything trapped during the back flush and get a clear forward flow.

|

| Media Filter with Top-mounted Control Valve |

|

| New, Larger Cartridge Filters |

And remember that large hammer that I've been swinging around? Well, another frustration throughout my water maker ownership had been figuring out which filter or filters are plugged and which are not. It's always been a guessing game, and has made if very difficult to figure out how to fix the filtration problems.

The solution was to add pressure sensors between each filtration stage so I could see exactly what the pressure drop is across each filter, and hence which filters were plugging up and which were fine. I did this using our existing Maretron monitoring system, and pressure transducers.

|

| Pressure Transducers |

Getting back to back flushing.... to get a good back flush, there needs to be enough water flow to agitate the media to shake loose all the trapped material. With too little flow, the media doesn't really get cleaned. From the reading I could find, a back flush rate of 3-5 times the forward filtering rate is what was required, and I honestly didn't know if the pump that came with the water maker could adequately back flush, but figured I'd give it a try and see.

I ran for a year with this new setup, and wow, what a difference. The original 2” filters were only good for about 8hr of run time before cleaning was required. With the media filter and the big blue filters, I only changed the fabric filters as part of annually scheduled maintenance. They never plugged up. I back flush the media filter about every 8hrs of run time, and it’s really easy to do. Just move the filter control valve to back flush, and turn on the pump. I installed an “Auto/Manual On” switch for the boost pump that gets switched to “Manual On” to run the pump for back flush, and is left in Auto for normal operation. I typically back flush for 15-30 minutes. You can hold a light up to the back side of the media filter and see the cloud of crud when you start the back flush, and see it clear over time.

This all worked very well, however by the end of the season I was having more and more trouble back flushing, so went back to the drawing board researching filter media and back flush flow rates. The good news is that with the pressure gauges, I could tell that the problem was the media filter and not the fabric filters. I was catching all the microbial material, but wasn't getting rid of it.

In my research I found a filter material called Micro-Z that is now part of Parker's product line. The material provides filtering down to 5 microns, and is much easier to back flush requiring only 1x the forward flow. So I gave it a try, and that was the key to success. I’ve been running for 3 years now with the stuff, and it still filters and back flushes great with the Spectra boost pumps.

|

| Schematic of final system |

Another challenge is fresh water flush. After running a water maker, you flush it with fresh water. With the media filter, plus the big blue filters, there is a much larger volume to flush. The flush water is first run through a charcoal filter to remove any chlorine which will otherwise ruin the water maker. For proper filtering, run can only run water through this filter at a limited rate, and that constrains how fast you can flush the water maker. What I discovered that there is a limit to the flush time in the Spectra controller, and it is actually too short. Even at max flush time, I was still getting salt content readings that were too high. So instead I set the flush time to 1/2 what’s needed, and after the automatic flush at the end of making water, I just manually trigger a second flush to finish the job. It's not ideal, but works.

I would love to get Spectra to increase the allowed flush timer, and their new controller system may be able to do it. I'm waiting for confirmation as I write this.